Temperature prediction for wire rod pickling plant management

Subject:

Industrial application · Pickling industry · Stainless steel · Dynamic model · Temperature forecasting

Publication date:

Publisher version:

Citación:

Abstract:

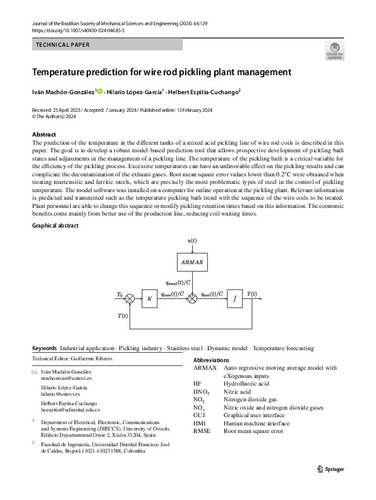

The prediction of the temperature in the different tanks of a mixed acid pickling line of wire rod coils is described in this paper. The goal is to develop a robust model-based prediction tool that allows prospective development of pickling bath states and adjustments in the management of a pickling line. The temperature of the pickling bath is a critical variable for the efficiency of the pickling process. Excessive temperatures can have an unfavorable effect on the pickling results and can complicate the decontamination of the exhaust gases. Root mean square error values lower than 0.2◦ C were obtained when treating martensitic and ferritic steels, which are precisely the most problematic types of steel in the control of pickling temperature. The model software was installed on a computer for online operation at the pickling plant. Relevant information is predicted and transmitted such as the temperature pickling bath trend with the sequence of the wire coils to be treated. Plant personnel are able to change this sequence or modify pickling retention times based on this information. The economic benefits come mainly from better use of the production line, reducing coil waiting times.

The prediction of the temperature in the different tanks of a mixed acid pickling line of wire rod coils is described in this paper. The goal is to develop a robust model-based prediction tool that allows prospective development of pickling bath states and adjustments in the management of a pickling line. The temperature of the pickling bath is a critical variable for the efficiency of the pickling process. Excessive temperatures can have an unfavorable effect on the pickling results and can complicate the decontamination of the exhaust gases. Root mean square error values lower than 0.2◦ C were obtained when treating martensitic and ferritic steels, which are precisely the most problematic types of steel in the control of pickling temperature. The model software was installed on a computer for online operation at the pickling plant. Relevant information is predicted and transmitted such as the temperature pickling bath trend with the sequence of the wire coils to be treated. Plant personnel are able to change this sequence or modify pickling retention times based on this information. The economic benefits come mainly from better use of the production line, reducing coil waiting times.

Patrocinado por:

The authors would like to express their gratitude for the financial support offered by the Commission of the European Communities, European Coal and Steel (ECSC), supporting MACOPILOT project “Optimisation of the mixed-acid online monitoring and control in stainless steel pickling plants” with 709694 as agreement number.

Collections

Files in this item