High-efficiency LED driver without electrolytic capacitor for street lighting

Publication date:

Editorial:

IEEE

Publisher version:

Descripción física:

Abstract:

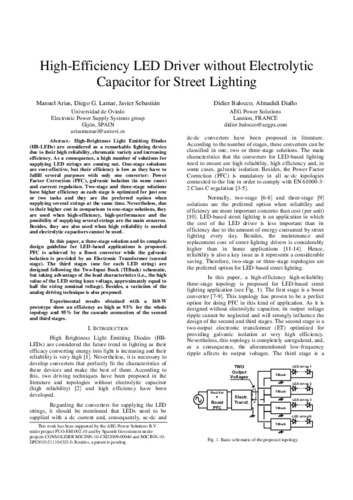

High-Brightness Light Emitting Diodes (HB-LEDs) are considered as a remarkable lighting device due to their high reliability, chromatic variety and increasing efficiency. As a consequence, a high number of solutions for supplying LED strings are coming out. One-stage solutions are cost-effective, but their efficiency is low as they have to fulfill several purposes with only one converter: Power Factor Correction (PFC), galvanic isolation (in some cases) and current regulation. Two-stage and three-stage solutions have higher efficiency as each stage is optimized for just one or two tasks and they are the preferred option when supplying several strings at the same time. Nevertheless, due to their higher cost in comparison to one-stage solutions, they are used when high-efficiency, high-performance and the possibility of supplying several strings are the main concerns. Besides, they are also used when high reliability is needed and electrolytic capacitors cannot be used. In this paper, a three-stage solution and its complete design guideline for LED-based applications is proposed. PFC is achieved by a Boost converter while the galvanic isolation is provided by an Electronic Transformer (second stage). The third stages (one for each LED string) are designed following the TIBuck schematic, but taking advantage of the load characteristics (i.e., the high value of the LED string knee voltage, approximately equal to half the string nominal voltage). Besides, a variation of the analog driving technique is also proposed. Experimental results obtained with a 160-W prototype show an efficiency as high as 93% for the whole topology and 95% for the cascade connection of the second and third stages

High-Brightness Light Emitting Diodes (HB-LEDs) are considered as a remarkable lighting device due to their high reliability, chromatic variety and increasing efficiency. As a consequence, a high number of solutions for supplying LED strings are coming out. One-stage solutions are cost-effective, but their efficiency is low as they have to fulfill several purposes with only one converter: Power Factor Correction (PFC), galvanic isolation (in some cases) and current regulation. Two-stage and three-stage solutions have higher efficiency as each stage is optimized for just one or two tasks and they are the preferred option when supplying several strings at the same time. Nevertheless, due to their higher cost in comparison to one-stage solutions, they are used when high-efficiency, high-performance and the possibility of supplying several strings are the main concerns. Besides, they are also used when high reliability is needed and electrolytic capacitors cannot be used. In this paper, a three-stage solution and its complete design guideline for LED-based applications is proposed. PFC is achieved by a Boost converter while the galvanic isolation is provided by an Electronic Transformer (second stage). The third stages (one for each LED string) are designed following the TIBuck schematic, but taking advantage of the load characteristics (i.e., the high value of the LED string knee voltage, approximately equal to half the string nominal voltage). Besides, a variation of the analog driving technique is also proposed. Experimental results obtained with a 160-W prototype show an efficiency as high as 93% for the whole topology and 95% for the cascade connection of the second and third stages

ISBN:

Patrocinado por:

This work has been supported by the AEG Power Solutions B.V. under project FUO-EM-002-10 and by Spanish Government under projects CONSOLIDER MICINN-10-CSD2009-00046 and MICINN-10- DPI2010-21110-C02-0

Collections

Files in this item