Implementation of a virtual sensor on a hot dip galvanizing line for zinc coating thickness estimation

Fecha de publicación:

Editorial:

EDP Sciences

Versión del editor:

Citación:

Descripción física:

Resumen:

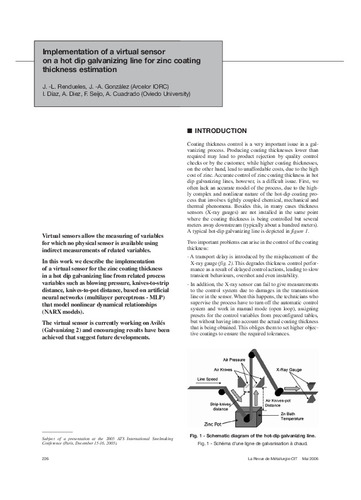

Virtual sensors allow the measuring of variables for which no physical sensor is available using indirect measurements of related variables. In this work we describe the implementation of a virtual sensor for the zinc coating thickness in a hot dip galvanizing line from related process variables such as blowing pressure, knives-to-strip distance, knives-topot distance, etc., based on artificial neural networks that model nonlinear dynamical relationships. The virtual sensor is currently working on Avilés Galvanizing 2

Virtual sensors allow the measuring of variables for which no physical sensor is available using indirect measurements of related variables. In this work we describe the implementation of a virtual sensor for the zinc coating thickness in a hot dip galvanizing line from related process variables such as blowing pressure, knives-to-strip distance, knives-topot distance, etc., based on artificial neural networks that model nonlinear dynamical relationships. The virtual sensor is currently working on Avilés Galvanizing 2

ISSN:

Colecciones

Ficheros en el ítem